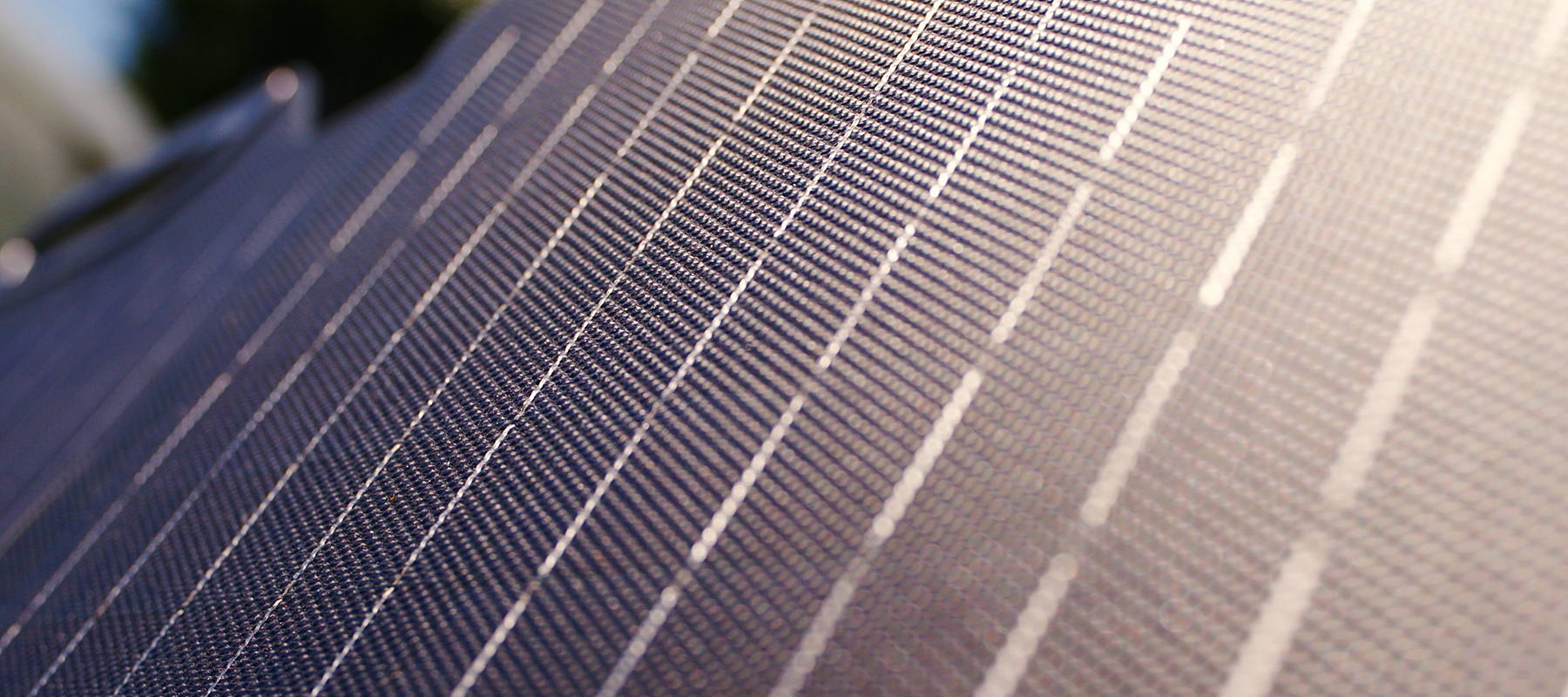

1. Classification of solar cells

Subscribe

To join our mailing list and never miss a BigBlue technology update!

2. History and the development of crystalline silicon solar cell

Media News

May 28th, 2022

Trending Articles

June 06th, 2022

October 11st, 2022

3. Advantages of monocrystalline silicon solar panels

Since the commercialization and application of solar panels on Earth in the mid-1970s, crystalline silicon has dominated the market as a basic material used in solar panels.

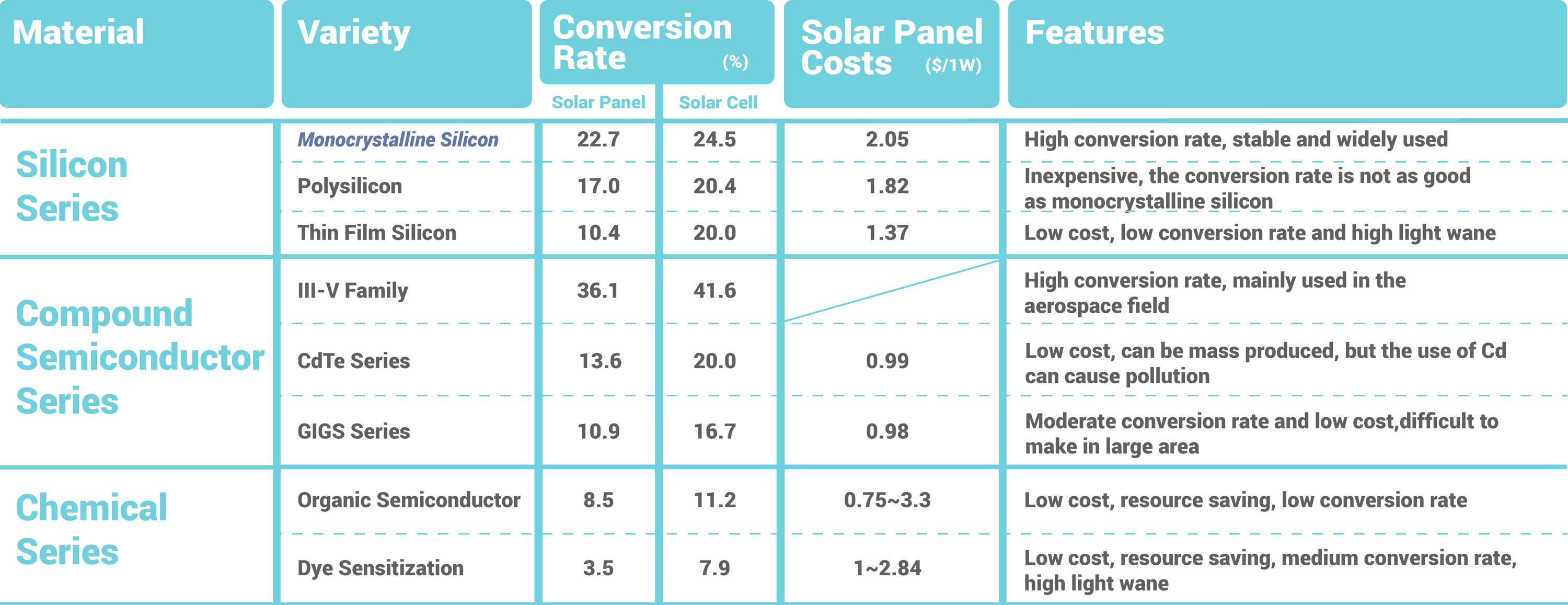

By the crystalline silicon type, solar cells can be classified into monocrystalline silicon, polycrystalline silicon, thin film crystalline silicon and amorphous silicon solar cells. The invention of polycrystalline silicon solar cells makes it possible to mass produce large-size square silicon ingots suitable for solar cell production, which requires simple manufacturing equipment and process, lower quality and less quantity of silicon. Thus, the production cost of solar cells is greatly reduced.

However, because of the material and process defects (such as grain boundaries and dislocations, micro-defects, impurities and transition group metal contamination in the manufacturing process), the conversion efficiency of polycrystalline silicon solar cells is very low.

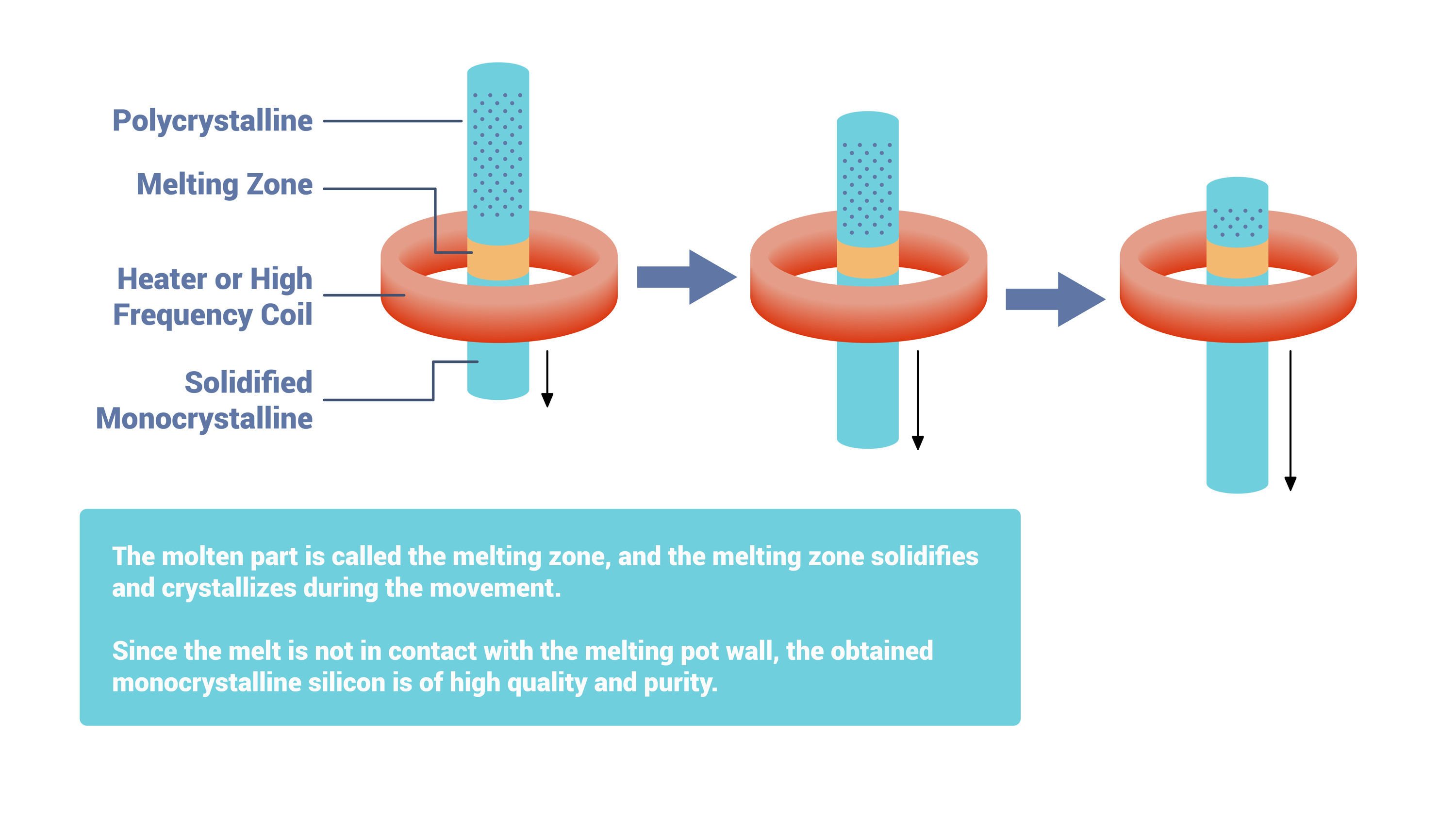

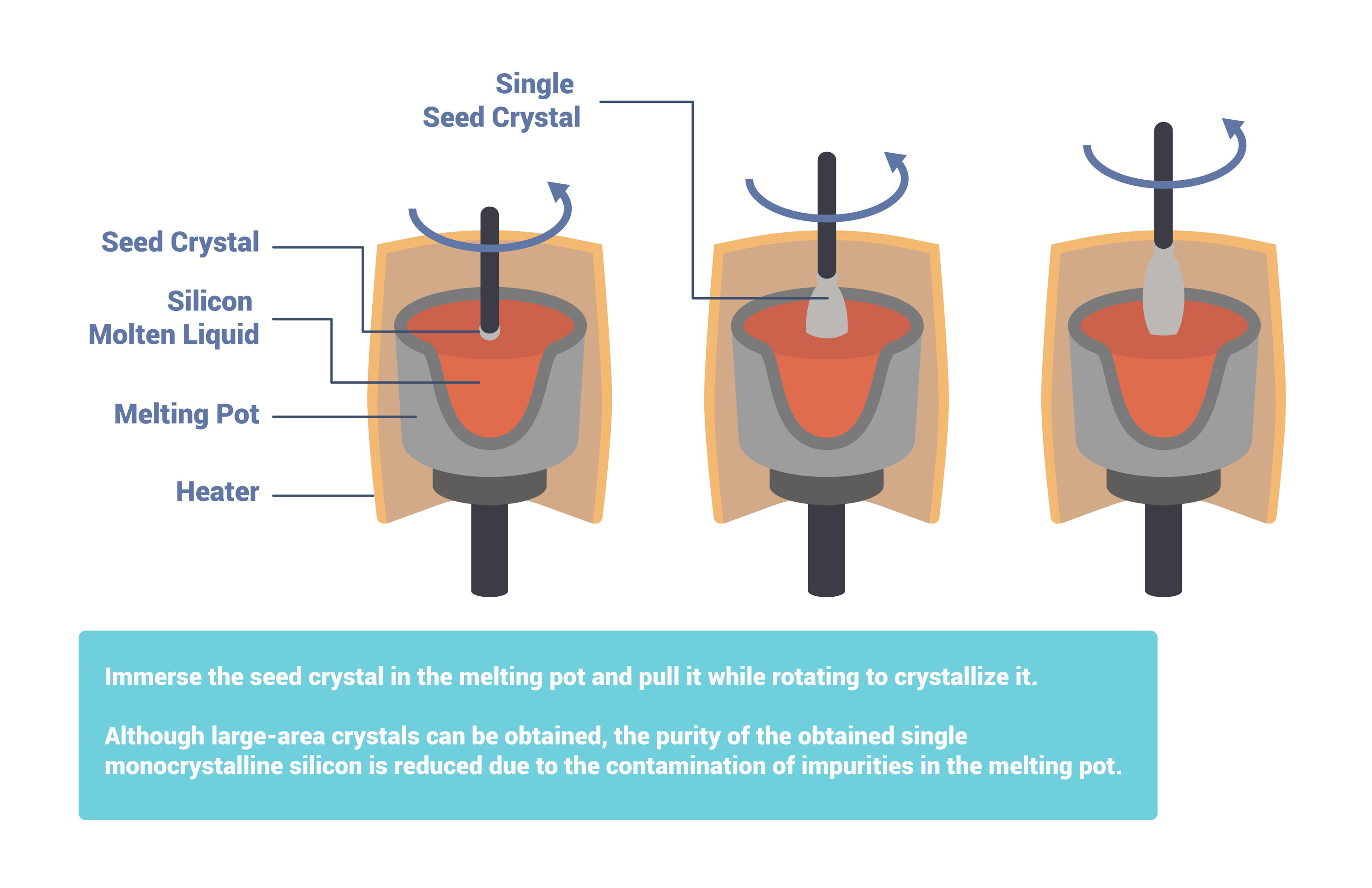

Produced from high-purity silicon grown by the floating zone (FZ) or Czochralski (CZ) process, monocrystalline solar cells have an average conversion efficiency of about 24%, which is 5% higher than that of polycrystalline silicon solar cells.

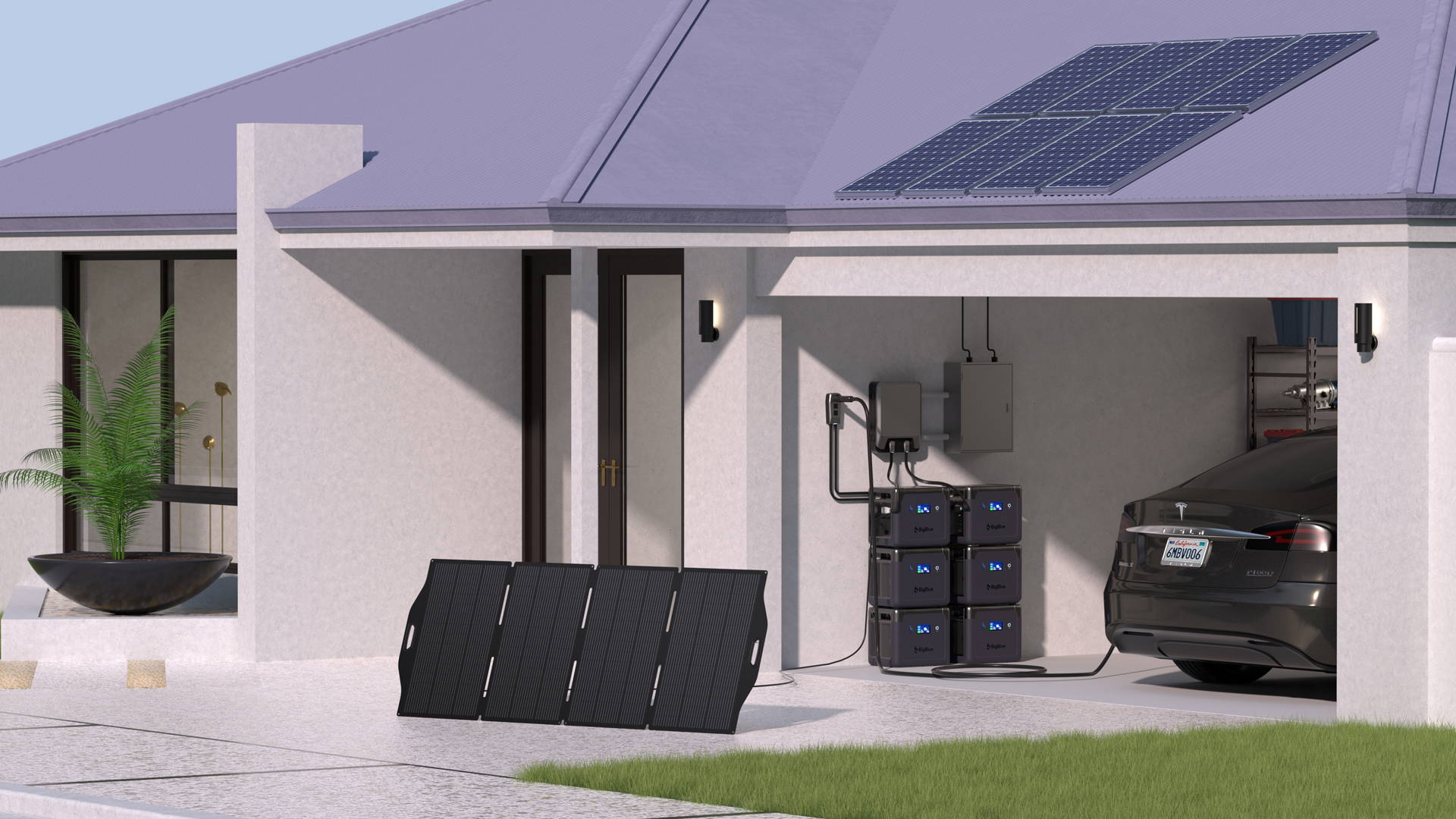

As the photovoltaic industry develops, the cost of monocrystalline silicon solar panels is continually reduced to nearly the same as the cost of polycrystalline silicon solar panels. Because of its rich reserve, stable performance, non-toxic characteristics and the constantly increasing conversion efficiency, monocrystalline silicon has become the most common material used in solar panels in the market.

4. The future development trend of solar panel materials

From the perspective of solid-state physics, silicon is not actually the most ideal photovoltaic material, because as an indirect band gap semiconductor material it does not absorb light very well. Therefore, studying alternative photovoltaic materials has become a trend. Cadmium telluride (CdTe), copper indium selenide (CuInSe2) and perovskite are considered to be three promising photovoltaic materials. So far, some progress has been made in the research of these materials. However, there is still a long way to go for these alternatives to be used to mass-produce solar cells and replace crystalline silicon.

BigBlue, founded in 2015, is a pioneer of the solar generator industry and a global top-selling solar generator brand recognized by over 100 authorized media and organizations worldwide. Our products include CellPowa series power station and SolarPowa series solar panl. With over 7 years of experience in the field, BigBlue is now a global energy professional brand, and one of the world’s biggest manufacturers of outdoor solar utilities. From day one of the brand, BigBlue aims to solve people’s worries about lacking power by its clean and renewable energy solutions for individuals, families, businesses and societies, helping people to create an infinite future. Learn more >